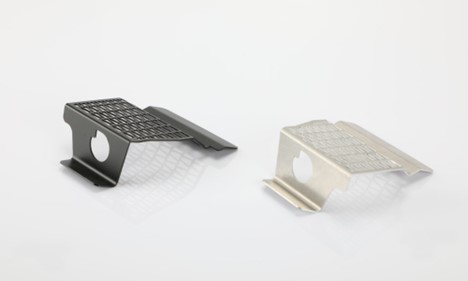

Rapid sheet metal fabrication has emerged as one of the most famous ways of designing prototypes before scaling up any commercial and industrial process. Ranging from designing automotive parts to construction parts to metal furniture, rapid sheet metal prototyping provides the easiest way of designing prototypes in a wide-ranging industry. The low weight, easy handling, and ductile behavior of rapid sheet metals make them a feasible material for prototyping.

What Is Rapid Sheet Metal Fabrication

Rapid Metal sheet fabrication is a technique of converting metal sheets into different products and structures. At the prototype level, these metal sheets are turned into a small prototype, which is then tested before being converted into the final product. Manufacturers use a series of processes to convert the flat metal sheets into the fabricated product.

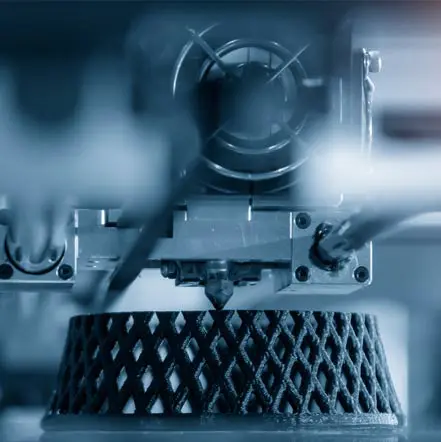

Manufacturing Methods For Rapid Sheet Metals

Rapid sheet metal fabrication is comprised of various steps, as detailed below:

Cutting

As the name suggests, the metal sheets are cut down into desired shapes at this stage. Most often, manufacturers start with a rectangular metal sheet which they cut down as per the shape of the required prototype.

Stamping

At this stage, flat metal sheets are converted into various shapes using different tools. These tools are used to apply a shear force to carry out the stamping process.

Bending

During bending, the metal sheets are bent using press brakes and other equipment like rolling machines. Bending is a sophisticated process, which means that manufacturers must carry out this process with extreme care. Otherwise, the metal sheets can be deformed.

Punching

Punching is a process of drilling holes in metal sheets using a punch and a die. The material employed in this process uses shear force to punch holes in the sheets. Once these holes are created, the die collects all the scrap material accumulated in the process.

Welding

This is the final stage in prototyping sheet metal. During welding, different parts of metal sheets are joined together using a wide variety of welding techniques.

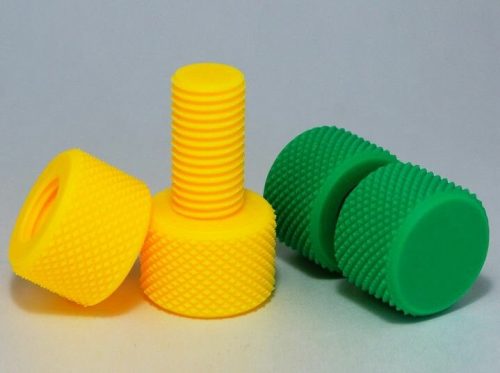

Materials Used In Rapid Sheet Metals

Various materials are used for rapid metal sheet fabrication, including:

Bronze

Due to its exceptional abilities of corrosion resistance, antimicrobial properties, and formability, bronze is widely used in rapid sheet metal fabrication for electrical, medical, and marine components.

Stainless Steel

Stainless steel is easy to use, not to mention that it requires low maintenance. Not only this, but it can withstand high temperatures, which makes it a perfect fit for rapid sheet metals.

Aluminum

Aluminum is cost-effective, lightweight, corrosion-resistant, and versatile material, due to which it is widely employed in rapid sheet metal fabrication.

Copper

Copper is also famous for metal sheet fabrication due to its high malleability, ductility, antimicrobial properties, corrosion resistance, and high electric and heat conduction.

Cold Rolled Sheet

Cold-rolled sheets provide highly impressive surfaces, which are necessary for prototypes. These sheets have high tolerances, concentricity, and surface conditions which make them appealing for rapid metal sheet fabrication.

Galvanized Steel

Galvanized steel is easy to maintain and cost-effective, while they have impressive longevity and aesthetic appeal at the same time. Likewise, galvanized steel has an easy inspection process, so it is best suitable for most prototyping applications.

CRAFTVIF Recommendations

CRAFTVIF provides impressive rapid metal sheet fabrication services for a range of industries. We employ a full range of techniques, including cutting, stamping, bending, punching, and welding, to manufacture state-of-the-art fabrications.

CRAFTVIF is equipped with all the necessary certifications, including ISO900:2021, which has helped them in winning the trust of thousands of customers worldwide. We are readily available for new projects, which means that you can easily access them for any metal sheet fabrication. Our capability of designing fabrications based on highly customized needs sets us apart from others.