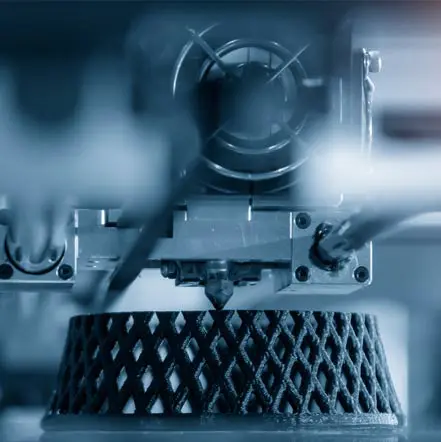

In the whole process of hand plate processing, after selecting the appropriate processing method CNC processing or 3D printing, after the processing is completed, most hand boards need to be surface treated. Meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product.

There are dozens of surface treatment processes for prototyping. As a large-scale prototyping factory, Kaiao can provide most of the surface treatment requirements for prototyping, and has a standardized production process.

Surface Treatment: Surface Painting

Surface painting is one of the most widely used surface processes.

Spraying has the following advantages:

- It can cover the surface defects of the workpiece after forming;

- A variety of colors, different gloss levels, different visual effects and a variety of different feel can be obtained by spraying;

- Enhance the hardness and scratch resistance of the workpiece surface;

- The effects of spraying are: matte, semi-matte, high-gloss, various colors, various textures, etched patterns, brushed effects, leather effects, elastic feel effects (rubber paint), etc.

Surface Treatment: Sandpaper Grinding

Sandpaper grinding can be carried out by hand or by belt sander equipment. It is the most common and widely used technology for post-polishing of 3D printed parts.

Be careful with sanding when dealing with smaller parts, as it is reciprocating by hand or by machine.

If the parts have minimum requirements for accuracy and durability, do not over-polish, and calculate how much material to be polished, otherwise the parts will be deformed and scrapped due to excessive polishing.

Polishing is a modification process that uses flexible polishing tools and abrasive particles, or other polishing media to modify the surface of the workpiece on the basis of grinding.

Polishing does not improve the dimensional accuracy or geometric accuracy of the workpiece, but aims at smooth surface or mirror gloss, and sometimes it is also used to eliminate gloss.

The surface roughness of the workpiece after the polishing process can generally reach Ra0.63 ~ 0.01 microns. Due to the very high grinding and polishing requirements of PMMA transparent workpieces, the price of PMMA transparent workpieces is relatively expensive.

Surface Treatment: Sand Blasting

Sand blasting is a process in which compressed air is used as the power to form a high-speed jet beam to spray the spray material onto the surface of the workpiece at a high speed.

This process can enable the workpiece to obtain a certain degree of cleanliness and different roughness, improve the mechanical properties of the workpiece surface, increase the adhesion between the workpiece and the paint coating, prolong the durability of the paint film, and also help the leveling and smoothing of the paint. Decorate.

Kaiao sandblasting can be completed in about 5 to 10 minutes. After treatment, the surface of the product is smooth and has a uniform matte effect.

Blast media are usually small finely ground thermoplastic particles. They are durable and can be sprayed with light to severe wear.

Surface Treatment: Silkscreen

Silkscreen is a type of printing that prints patterns where needed. Frame the screen plate with a frame, and then the place where the screen is hollowed out is the pattern to be screen-printed, apply the dye to the screen, and finally scrape the dye into the hollow pattern with a scraper, and then the screen-printing is completed.

General product text or logo will use silk screen printing. Common products that require silk screen printing include electrical appliances, toys and daily necessities. Screen printing can only be used for flat products, so uneven and curved products cannot be screened.

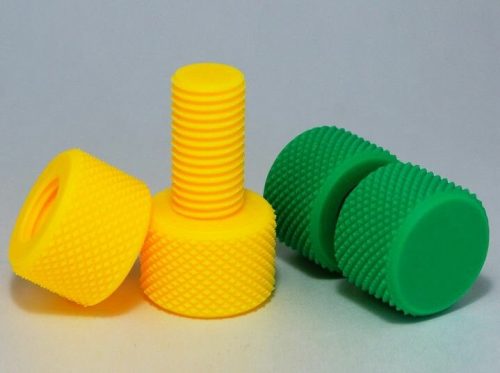

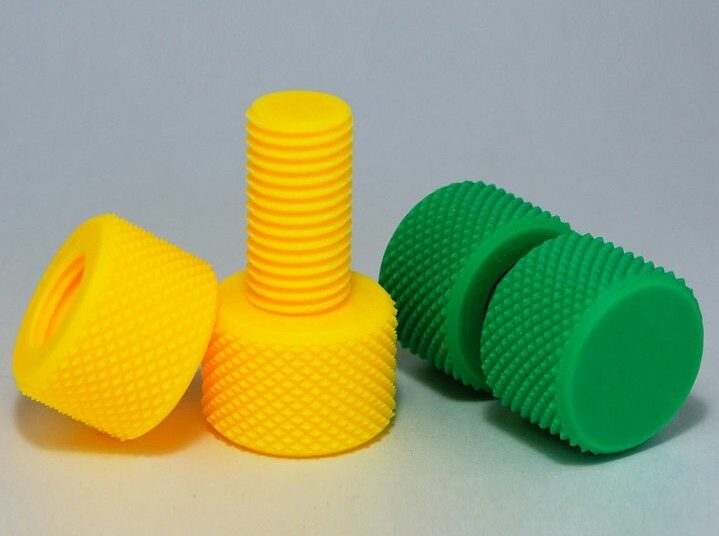

Steam Smooth

The 3D-printed parts are dipped in steam cans with a liquid that has reached boiling point at the bottom. The rising vapor melts a layer of about 2 microns on the surface of the part, turning it smooth and shiny in seconds.

Vapor smoothing technology is widely used in consumer electronics, prototyping and medical applications. This method has little effect on the accuracy, but the disadvantage is that there is a size limit, and the effect is not very good for products printed with high heat-resistant materials.

In order to better meet the actual needs of users in various industries, Kaiao will launch the highest quality products for customers with exquisite professional skills and high professionalism. Further refine the 3D printing technology, develop new application models, and fully meet the production and manufacturing needs of customers.