A metal prototype is a physical representation of a product before it is mass-produced on an industrial scale. These prototypes can be made using various materials such as aluminum, copper, and stainless steel. The goal of making these prototypes can be to receive feedback from others, to test the design, or to secure investment funding for the project.

In this article, we discuss the best ways to make metal prototypes, including the best shapes and methods.

It also discusses the pros and cons of various types of prototypes, and which prototype is more favorable.

What Is Metal Prototype?

The prototype is a model, copy, or specimen of an item to be made. It is meant to test a new design to make sure that it works and meets all requirements. A prototype is often used to test the manufacturability of a design. A prototype is made before manufacturing begins and it may be used as a model to refine the design.

A metal prototype is identical in form and function to the final product, made of metal instead of plastic or any other material. Metal prototypes are typically used for metal product development and testing, for example for testing how a part performs under load or in extreme temperatures. They may also be used for more routine tasks, such as receiving gripe from users or testing out product decoration.

The things that metal prototypes are made of are stronger than any other material. And they are designed to withstand high-impact loading and extreme temperatures. So when the final products are made with metal parts, they can be used in many places where plastic parts cannot.

Plastic Prototype Vs Metal Prototype

Plastic Prototype

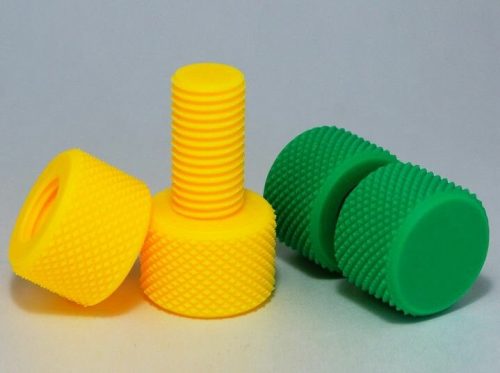

A plastic prototype is a model that replicates the actual look and feel of the end product using plastics. It can be used to test the fit of parts, assure quality, and design functionality of the product. Plastic prototypes are used by designers to get client feedback before the product is even in development.

Plastic prototypes are also commonly used for testing out new functionality that may be called for in the design. For example, a designer may want to test out a new type of hinge before parts are made for an actual product to make sure it works as expected.

- Pros

Low cost, quick turnaround time

- Cons

Not as strong as metal, not for load/stress test

Metal Prototype

A metal prototype is identical in form and function to the final product, made of metal instead of plastic or any other material. Metal prototypes are typically used for metal product development and testing, for example for testing how a part performs under load or in extreme temperatures.

They may also be used for more routine tasks, such as receiving gripe from users or testing out product decoration. The things that metal prototypes are made of are stronger than any other material. And they are designed to withstand high-impact loading and extreme temperatures.

- Pros

High impact strength, extreme temperature resistance

- Cons

cost is high

Why Choose A Metal Prototype Instead Of A Plastic Prototype?

Metal prototypes are superior to plastic prototypes in several ways.

Workability

Metal can be machined, polished, and finished more than plastics. It can also be stamped, forged, die-cast, shaped, and bent into many different forms. With plastic, you would need to make an entire mold for each of these processes.

Prototyping Time Frame

With a metal prototype, you can go from concept design to functional prototype a lot faster than with a plastic one because of the ease with which it is machined. With plastics you have to 3D print your model, wait for it to cool down before you can test it out, and then fix any changes that need to be made until the design is finalized.

Weight

There is no weight in cutting and machining down a plastic model so it uses up a lot more material to produce. Plastic models are also flimsy and have thin sheets of material, allowing them to flex and be easily broken. Metal models are also heavier but can be machined to last for much longer, making them a much better investment for prototype manufacturing.

Metal prototypes can easily be used for Load testing, where loads are placed upon them to check if they will meet the required strength. This is because of their strength, which allows the prototyping team to know the load required or how far it needs stretching out before breaking under-stress tests.

Methods To Make Metal Prototype

CNC Rapid Metal Prototype

The most common way for a metal prototype to be designed is through a computer-aided design system. A CAD program acts as the designer’s guide and allows them to see the prototype from all angles, making it easier for the designer to make decisions and modify the design as necessary.

A CNC rapid prototyping machine is used for this purpose. With this machine, designers can 3D print, cut, bend and drill parts to create their desired metal prototype. All of these processes are done in a very short amount of time.

- Pros

Low cost, Design freedom, Material selection

- Cons

Wastage of material

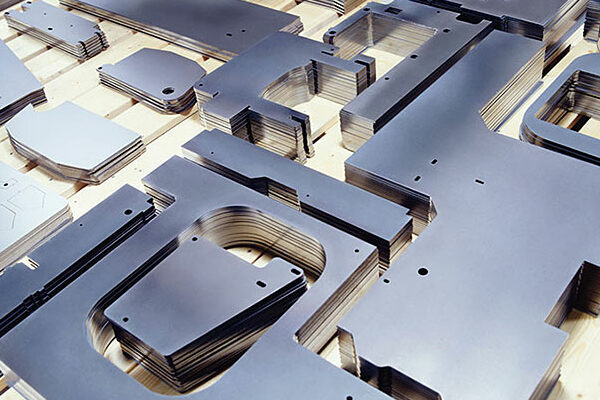

Sheet Metal Prototyping

It refers to cutting metal sheets into specific shapes and sizes to make prototypes. It also includes bending, folding, punching holes and joining metal sheets together with arc welding. Most kinds of materials can be used including aluminum, copper and stainless steel.

- Pros

Material selection, Welding, Good surface finish

- Cons

Cost is high, time-consuming, Not suitable for complex shapes

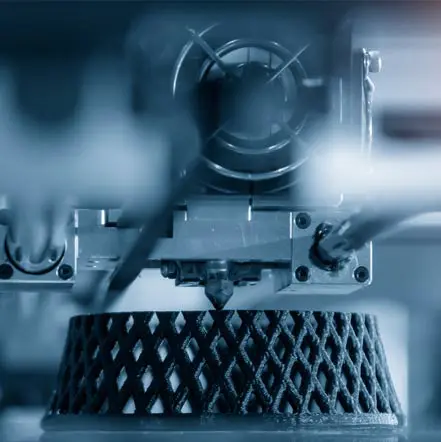

Metal 3D Printing Prototypes

It refers to a metal part is created by 3D printing technology. Tiny particulate material are melted and fused together layer by layer in the form of three dimensional objects. Different from common plastic manufacturing process,3D printer can build up the model layer by layer using metal powders (alloys) to create the desired prototype or product.

Metal 3D printers can print prototypes directly from CAD data without needing intermediate tooling or moulds.

- Pros

Low cost, Design freedom

- Cons

Low strength, Material selection

Metal Casting Prototypes

It refers to the molten metal being poured into a mold cavity to cool and solidify. The cooling process takes place in a matter of seconds and results in a finished product. It is an option that is used to create metal castings, including aluminum, brass, bronze and iron castings.

- Pros

Good surface finish, Material selection

- Cons

High cost, Time-consuming

How To Choose The Best Way To Make Metal Prototype

You can choose the best way to make metal prototypes by following these criteria,

Materials

Materials choice is one of the first things to consider when choosing a metal prototype. There are many different types of materials used in prototyping. For example, when building a plastic prototype, you would usually work with a material such as ABS or Polypropylene.

But for metal prototypes, the materials are changing on a daily basis. Newer metals are being developed and tested all the time. The most common ones you will find at companies today is Stainless Steel and Aluminum..

Functions Of Prototypes

Another thing to consider is how the metal prototype will be used. Depending on what you want to use the prototype for, you will have to choose the right prototyping method.

If your metal prototype is going to be used indoors a lot and is going to get a lot of wear and tear then you would want to use an outdoor material for your prototype. However, if your metal prototype needs to be machined in a very particular way then choose another material for it.

Cost And Time Benefits

Another thing to consider is the cost and time required for each of the different methods for making a prototype. For example, if you want to use an electric discharge machine then you will have to buy it, wait for it to be shipped and for it to arrive on your door step.

Then you will have take out all the pieces from the box and assemble them one by one. This would take a lot of time and you would want to do that as little as possible when it comes down to making your metal prototype.

Conclusion

So, this is all about the best ways to make metals prototypes. You can use any of the above given methods to create strong, cost-effective and durable metal prototypes for you or you can directly contact CRAFTVIF for this.

CRAFTVIF is a certified manufacturer, providing you the best prototyping fabrication services.

CRAFTVIF has engaged in plastic mold manufacturing industry and metal machining,machine forging and assembly,such as prototype,medium-volume production and low-volume production,for more than 30 years.

CRAFTVIF mainly provide service for automobile models manufacturers and molding plastic research institutes. The precise control of the injection molding process, the close cooperation with product development departments, all make sure that we provide customers with high quality prototype parts.